Effect of External Varying Magnetic Field on The Mixing of Ferrofluid

A lab-on-a-chip (LOC) is a device that integrates one or several laboratory functions on a single integrated circuit (commonly called a “chip”) of only millimeters to a few square centimeters to achieve automation and high-throughput screening. LOCs can handle extremely small fluid volumes down to less than pico-liters. Lab-on-a-chip devices are a subset of microelectromechanical systems (MEMS) devices are sometimes called “micro total analysis systems” (µTAS). LOCs may use microfluidics, the physics, manipulation, and study of minute amounts of fluids. However, strictly regarded “lab-on-a-chip” indicates generally the scaling of single or multiple lab processes down to chip-format, whereas “µTAS” is dedicated to the integration of the total sequence of lab processes to perform chemical analysis. The term “lab-on-a-chip” was introduced when it turned out that µTAS technologies were applicable for more than only analysis purposes.

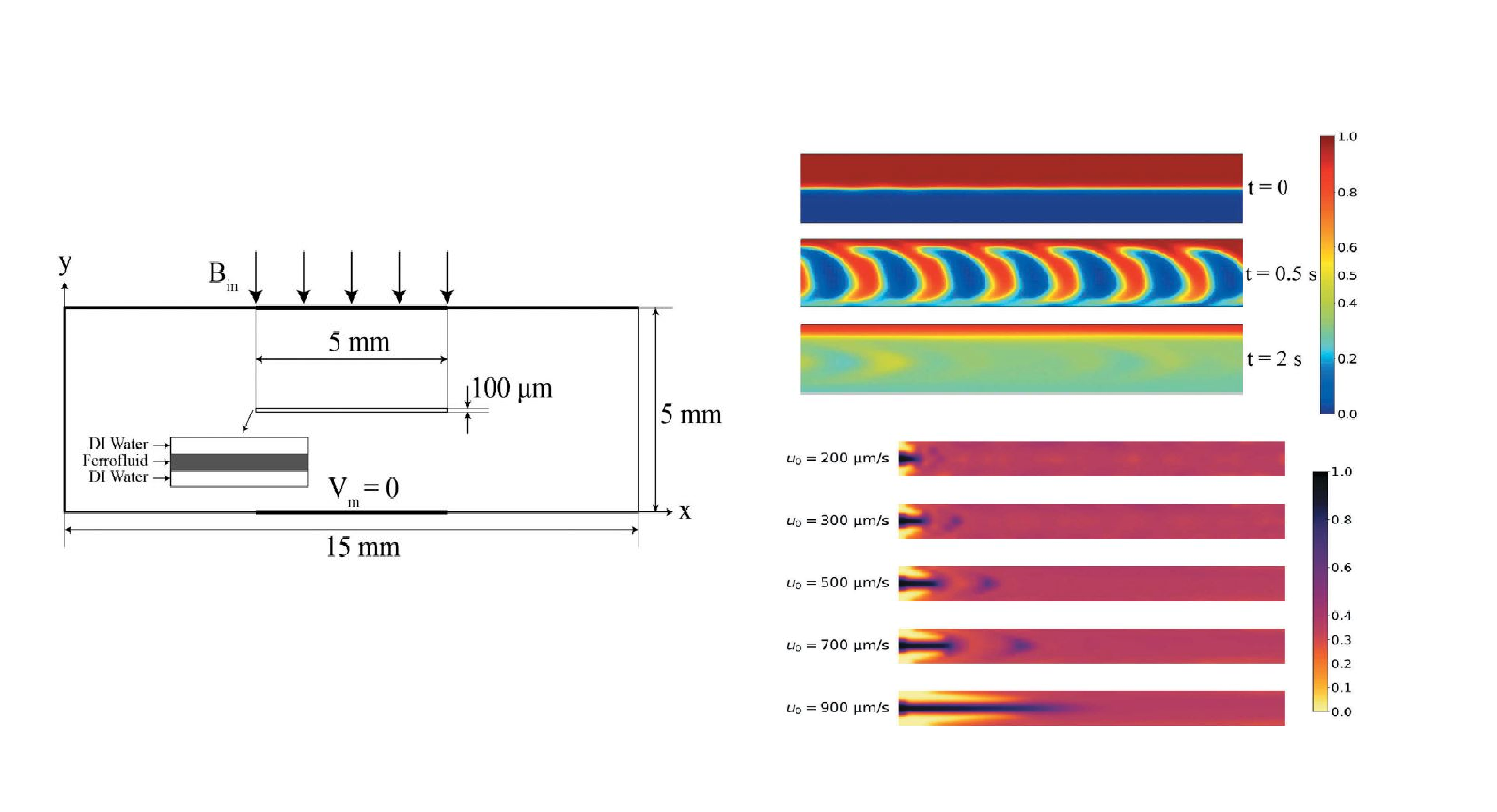

Energy-efficient mixing is vital for chemical and fuel processes. To this end, a flow-focusing configuration is proposed to investigate the effect of a uniform magnetic field on the mixing of a water-based ferrofluid with two streams of deionized water. An external and varying magnetic field is imposed on a straight microchannel, and the mixing between the ferrofluid and deionized waters is qualitatively and quantitatively measured.

A commercial code based on the finite-element method is used, and the simulations are validated by two experimental studies. For a magnetic flux density of 10 mT, a signal frequency of 1 Hz, a duty cycle of 0.3, an inlet velocity of 500 µm/s, and a relative inlet velocity of 0.5, an excellent mixing efficiency as high as 97.4 % is achieved after 1.5 s of the magnetic actuation. This model benefits from its low implementation cost and can help augment and develop energy-efficient lab-on-chip platforms.

Microfluidic systems are being used in applications such as biological analysis, biochemistry, and fuel cells. Microfluidic platforms offer miniaturization and small usage of solvents as well as energy. The miniaturization also provides precise control over the samples, and flows inside microfluidic components are typically laminar. Microfluidic platforms usually comprise sensors, pumps, detectors, valves, microreactors, and micromixers.

Studies investigating static magnetic fields and magnetic fields generated by permanent magnets are comprehensively conducted. However, the effects of varying external magnetic fields on the flow-focusing micromixers and the interactions of the magnetic field with the flow and concentration fields have not been investigated so far. No studies have investigated the effect of the duty cycle on the mixing under external magnetic actuation, and the interplay between the magnetic and flow fields has not been comprehensively detailed. Therefore, the purpose of this study is to numerically investigate the micromixing between a water-based ferrofluid and two streams of deionized water(DI) in a straight microchannel under an external varying magnetic field. The effects of the magnetic field strength (B0), the actuation frequency (f), the duty cycle of the varying magnetic field, the inlet velocity (u0), and the relative inlet velocity between ferrofluid and water streams are investigated to obtain an optimum mixing efficiency, a prerequisite for efficient microfluidic systems.

For the validation purpose, the induced horizontal magnetic force on a 1.2 µm particle is simulated, and the results are compared with that obtained by Suzuki, Ho, and Kasagi under their conditions (2004).

The mixing within magnetically actuated microsystems is complicated due to the intricate balance between the flow momentum and the magnetic force. To alleviate this complexity, we propose a simple and low-cost method to properly mix a stream of a water-based ferrofluid with two streams of DI water in a flow-focusing configuration. The effects of the magnetic flux density, the signal frequency and its duty cycle, the inlet velocity, and the relative inlet velocity are numerically investigated to achieve an almost perfect mixing. It is reported that the magnetic flux density should surpass a threshold to adequately expand the ferrofluid vertically, and this magnetic flux density should not be too high for the mixing efficiency to deteriorate. Higher frequency results in lower mixing efficiencies, and a duty cycle less than 0.5 at 1 Hz is seen to have an excellent effect on the micromixing performance. Inlet velocity also faces limitations and should be selected diligently. Too high or too low inlet velocities are deemed to worsen the mixing performance. Relative inlet velocity around 0.5 is concluded to provide an excellent mixing efficiency of 97.4% in only 1.5s. This proposed model can be easily exploited to help design low-cost and affordable external magnetic micromixers with minimal integration complexity and satisfy the urge to design energy-efficient solutions for microfluidic systems.

The paper detailing the proposed strategy Numerical investigation on the effect of external varying magnetic field on the mixing of ferrofluid with deionized water inside a microchannel for lab-on-chip systems, authored by Pr. Ghassemi, his senior student, Milad Saadat, and his colleague in sharif university, Dr. Mohammad Behshad Shafii, was recently published in the journal of Recovery, Utilization, and Environmental Effects on 26 Feb 2020.