A Neural Network Approach for Predicting Steel Properties

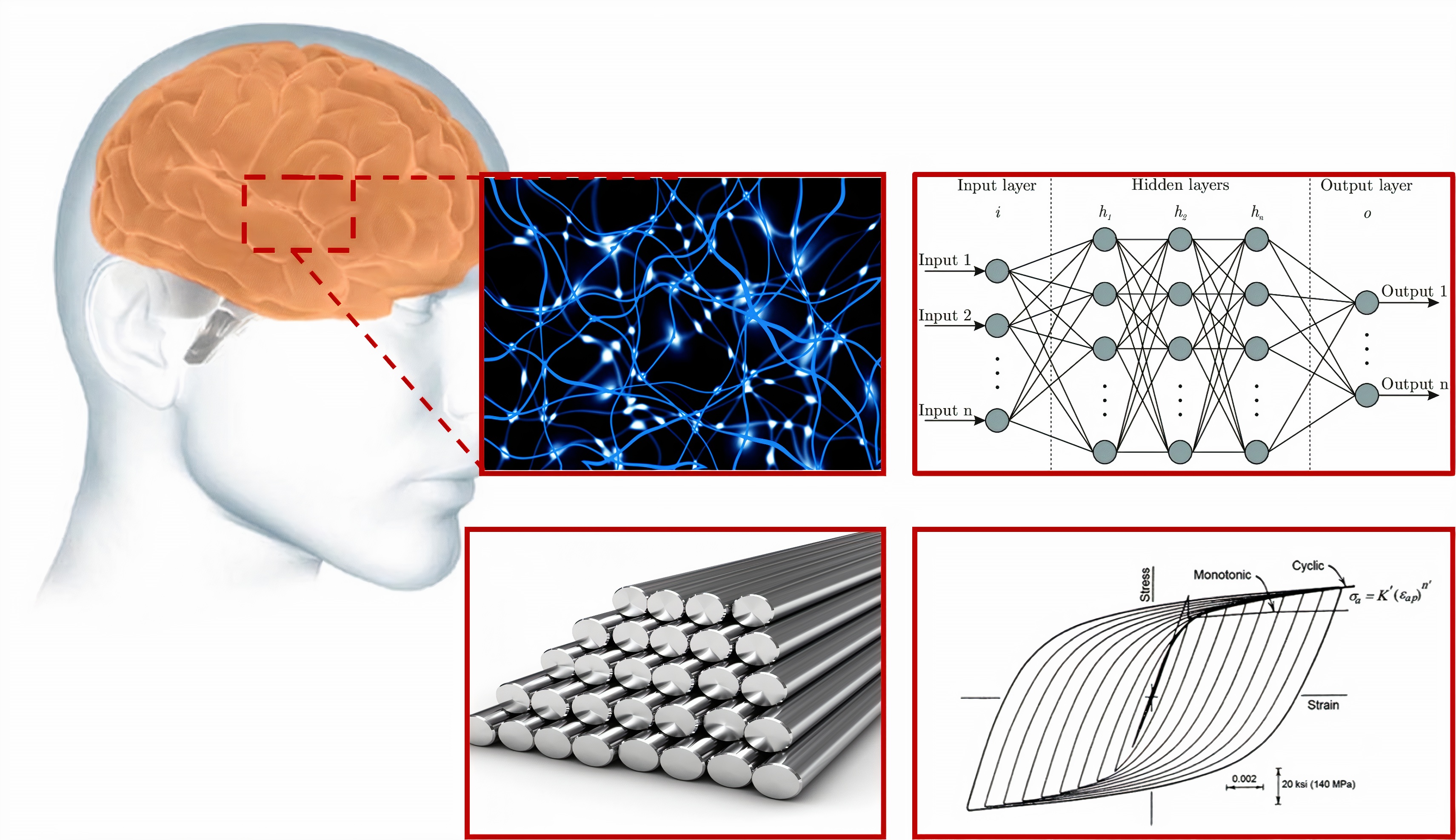

The subject of machine learning is based on living creatures, especially humans. According to this, we model human brains and attempt to create neural networks with the intelligence to learn on computers. Applying the structure of neurons and how they connect, we can reproduce complex nonlinear systems. This process generally involves step-by-step training by reducing network error at each epoch. We can settle the error function, depending on the needs of the network. There are different designs and types of neural networks that can be referred to as needed.

Steel is one of the essential alloys used by humans. This alloy is widely used in the water transfer network and the architecture of buildings, especially automobiles. As a result, it is crucial to know its properties to make the best use of this alloy. The mechanical properties of stress and strain are about how much force a material can withstand before hard deformation or breakdown occurs in steel.

Dr. Naser Naserifar, Assistant Professor of Mechanical Engineering, K.N. Toosi University of Technology, and his research team, worked on estimating the different mechanical properties of the steel material. The results show that the values obtained from the artificial neural network (ANN) method align with the experimental results.

This research’s objective is about one of the leading mechanical parameters of steel, fatigue life, which is defined based on stress and strain. It is worth mentioning that the relationship between the stress and strain obtained based on the cyclic response is more precise than the values acquired from the monotonic curves. It is because the inelastic deformation that occurs at the roots, is only captured in the cyclic loading curve. In an experimental study, three different methods of companion, incremental, and multiple-. It is worth mentioning that the relationship between the stress and strain obtained based on the cyclic response is more precise than the values acquired from the monotonic curves. It is because the inelastic deformation that occurs at the roots, is only captured in the cyclic loading curve. In an experimental study, three different methods of companion, incremental, and multiple-step methods are used to provide the cyclic stress-strain curve. However, these methods are expensive and time-consuming; hence, using numerical methods to estimate the mechanical properties of materials is of high importance. In steel, The Ramberg-Osgood equation represents the relationship between cyclic strain amplitude and cyclic stress amplitude. In this study, to capture the nonlinear behavior of the steel material, different parameters including cyclic strength coefficient (K), cyclic strain hardening exponent (n’), and modulus of elasticity obtained from the cyclic curve are employed.

In this study, the most popular ANN method, known as multi-layer perceptron (MPL), is used. In this method, the technique of back-propagation is widely used due to its effectiveness and simplicity. The multi-layered neural network consists of three parts, namely, input, hidden, and output layers. The equation for each segment is defined by different nonlinear activation functions such as step function, sigmoid function, and hyperbolic tangent function. The last function is used in this research due to its high efficiency. In this method, the weights and biases during the training process are determined to minimize the mean square error. Although there are different types of training algorithms, finding a suitable one to fit the specific problem is severe. However, the Levenberg-Marquardt (LM) algorithm is employed, which is based on second-order training speeds without computing the second order.

In the first step, the experimental data of 82 steel plates of steel represented in the literature are applied to verify the ANN model. This data includes the main mechanical specifications of steel, namely, the yield strength, ultimate tensile strength, Brinell hardness (BHN), the net area reduction rate (RA%), modulus of elasticity. In the following step, different combinations of these parameters are considered with a different number of neurons to find the best configurations. The regression analysis shows that the combination of yield stress, ultimate tensile strength, BHN, and RA% with eight neurons has the most accuracy to predict the cyclic strength and the cyclic strain hardening exponent coefficients. The combination yields the smallest mean relative error (MRE).

In conclusion, ANN is highly recommended to predict the cyclic strength coefficient (k’) and cyclic strain –hardening exponent (n’), which are two main parameters in the determination of the fatigue life of steel. The regression analysis shows that the mean relative error of the ANN method is less than that obtained from the Ramberg Osgood equation. The properties of the cyclic stress-strain curve obtained by ANN are of more accuracy than those obtained by the equations based on the low-cycle fatigue properties.

The article detailing the main idea – A neural network approach for predicting steel properties characterizing cyclic Ramberg–Osgood equation – authored by a team of researchers from Material Properties Research Laboratory (MPRL), Department of Mechanical Engineering, K. N Toosi University of Technology of Iran, was published in the Journal of Fatigue & Fracture of Engineering Materials & Structures in 2011.